When a gasket fails on flange connections, safety for people and materials is the most important thing.

Here we offer the optimum solution with SPRAY CONTROL!

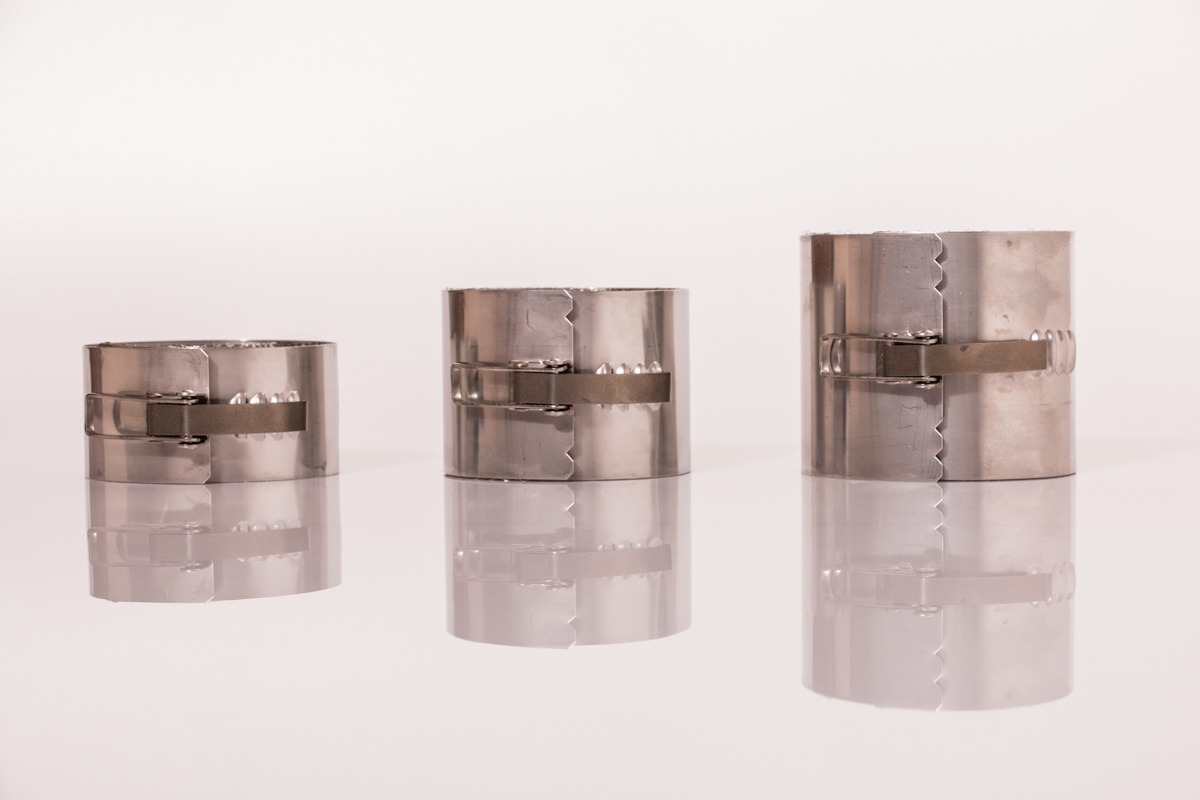

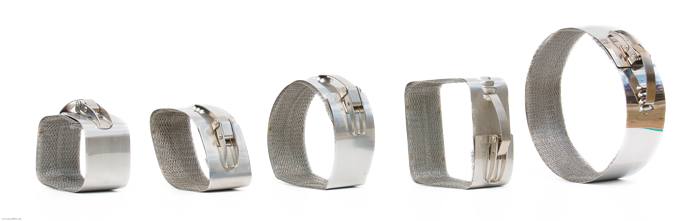

SPRAY CONTROL is the best and safest splash guard ring,

state-of-the-art technology.

SPRAY CONTROL guarantees absolute safety, regardless of the flange type or size of a flange connection on which the ring is mounted.

SPRAY CONTROL is supplied for all sizes according to DIN and ANSI.

Request a non-binding offer according to your specifications.

SPRAY CONTROL is resistant to aggressive, toxic environmental conditions as well as UV exposure and high temperatures, up to 600°C (1.112°F).

SPRAY CONTROL, safety first!

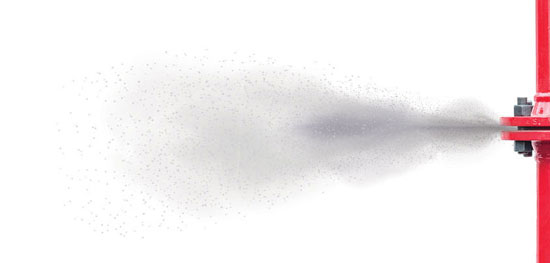

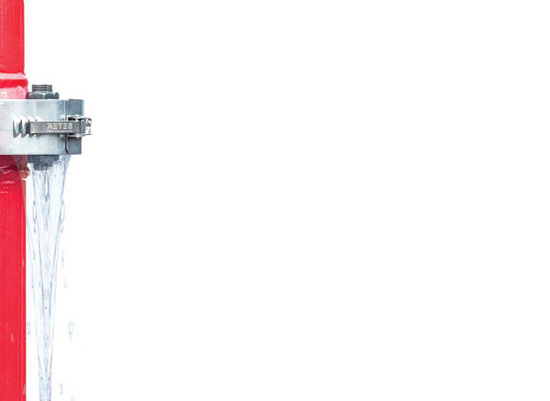

Our “Spray Control” flange protection in a simulation on a defective flange connection with up to 300 bar

Different sizes and shapes were tested at 100, 200 and 300 bar at each pressure for 10 minutes.

The same result with every test:

Our flange protection shows no signs of wear, deformation or defects.

We tested our Spray Control flange protection in a simulation at the renowned environmental simulation laboratory TREO in Hamburg.

Some of our clients